I really enjoyed making this piece, with a very pronounced angle tip (tanto style) and a thin handle with my halberdier accent. First I’ve done in this type with a traditional Japanese grind.

I really enjoyed making this piece, with a very pronounced angle tip (tanto style) and a thin handle with my halberdier accent. First I’ve done in this type with a traditional Japanese grind.

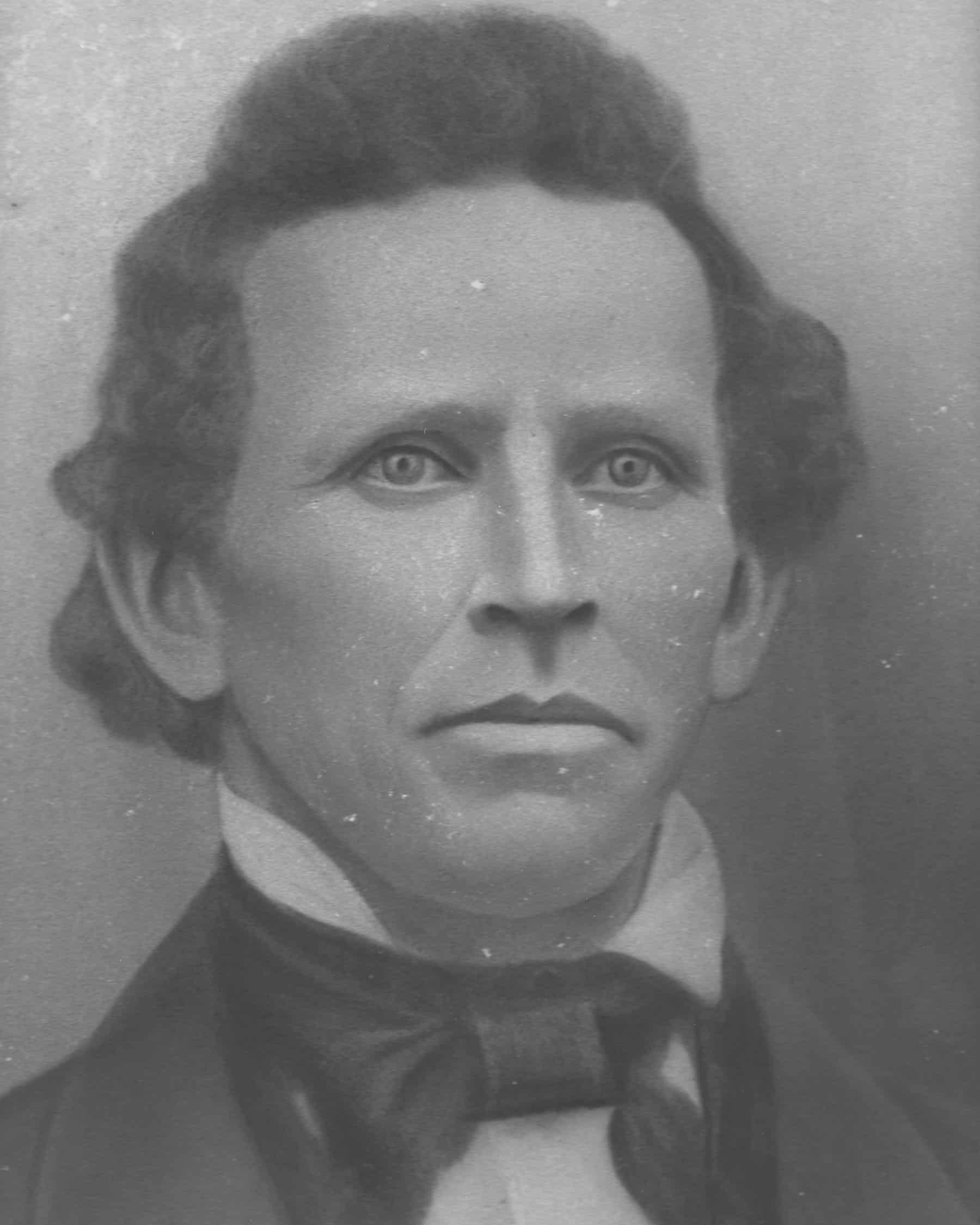

Sometimes I get a bit of history with the heirlooms that come into the shop.

This razor was in need of a new set of scales, and the edge required restoration. A bit of tarnish on the steel, but after holding it in my hands and taking a close look – it’s just age. One thing I cannot create.

I love blades like this. I want to keep the patina, and design alongside it. Not remove it. This tarnish is a sign that this razor has outlived us, and will continue to do so.

I restored this simply, and wanted to respect the steel as much as possible. The new handles I crafted are polished ox horn with a argentum silver wedge. Just a simple, traditional, elegant way to support a blade with a story.

Here’s the story of Thomas Melvin Smith, and this blade:

*account from the owner

Thomas Melvin Smith (1821-1908) was a soldier in the 2nd Co, 36th Rgt. of Confederate troops, a heavy artillery regiment that manned the guns at Fort Fisher, outside Wilmington, NC during the Civil War.

Fort Fisher was the Confederacy’s lifeline to the outside world due to the Union blockade and blockade runners frequently ran the blockade under the protective guns of the fort bringing badly needed medicine, ordinance, and supplies to the South.

All blockade runners had to carry a certain percentage of military goods on the inbound voyages and carried cotton to England on the outbound, but they were also allowed to bring in personal

merchandise which would sell for exorbitant prices to the beleaguered population.

Needless to say, not all blockade runners made it, and many ran aground off the beach by Fort Fisher. Since blockade runners ran the blockade at night, ships that ran aground were often unloaded in the darkness as much as possible before the Federal Fleet sighted the stranded ships at sunrise and shelled them into oblivion.

According to family lore, my grandfather helped to unload a stranded runner one night off the beach and procured this razor from the cargo. He took it home on furlough in late 1864.

Thomas Melvin Smith was captured with the entire garrison of the fort in Jan 1865 and sent to Elmira Prison in NY, where he miraculously survived and returned to NC in July of 1865.

From there, the blade was passed to his son, then grand-daughter, then to her daughter who gave it to her husband. I inherited the blade from him after he died in 1990.

Seems only like summer started last week here at the shop. Spending a great deal of time creating some custom razors that I’m thrilled to be posting soon. Also, really excited for some partnerships that will be announced soon!

Till then, I’ve posted some great new blades in my store, check it out here.

I can’t explain how happy it makes me when I get photos from folks using my blades.

Martin W. is just starting the journey with a straight, and picked up one of my beginner vintage kits that featured “The Artist” straight razor, and a very nice full grain vegetable tanned classic strop.

I don’t know whether it was the shipping overseas, or if he just wanted to put the blade to the test, but he decided the first shave would be with 5 days of growth. Trying this on a cartridge razor would quickly dull and choke it out, clogging the unnecessary layers of blades. As you can see above, a single blade, and a single pass is all you need.

I put a good deal of time into the edges of my work, and finish on a very rare vintage escher barber’s hone (one that many of the fine cutlers of the late 1800’s and early 1900’s would have used), and finish on one of my strops. Happy to see it’s shaving as hoped. And makes me even happier to see the blade got a great home.

Check out Martin’s razor Here.

-Christopher

A beautiful old blade, with a wavy smile.

Greaves was one of the first straight razor manufacturers in Sheffield to establish a “start to finish” razor all in house. Other cutlers were relying on a network of craftsmen, where Greaves was creating his pieces all under one roof.

This 1800’s blade is one of a kind, and I gladly honed it up and sent it to its lucky owner.

Many interesting custom straight razors are being finished and leaving my shop this week. I’m starting off the Monday with this razor, an all American inspired piece.

I used cherry wood for the handles, U.S. O1 tool steel for the blade, and styled the design to be similar to a wood cutting axe. It’s a 6/8ths wedge, and has a nice fit from toe to tip. Great in the hand.

Stay tuned, many more custom razors to be revealed…

A look at the tools I use to make custom straight razors.

The large hammer is what I used to make the handle drawn out (4lbs), and the little one (over 1.5 lb) is used for detail work, and performing wet forging to make impurities blast off the surface of the steel.

Most of my razors are forged with the rusted tongs, 1″ box jaws. They’ve become a close friend. The wolf Jaws (center) are used when I’m heat treating, or reaching areas of the forge/furnace that are tricky. The little tongs are for delicate and finish work.

Though very odd looking, this is something I use all day long. It’s a kamisori that I was frustrated with, and decided to scrap due to imperfections. I repurposed it as a push stick that assists me in the grinding process by adding extra support. It’s also a good reminder that good work takes time, and no matter what, I shouldn’t rush work.

This is a very rare rock.

This is a yellow green Escher Barber’s delight.

I use it to finish all my razor honings. This is the last stone used before I strop.

I purchased this stone and carefully removed the stickers (I’ve archived them).

This stone has been through many razors, and made many blades keen.

It sits atop a chamois that I use to wipe slurry and water away as I switch between stones.