I was very fortunate to grow with friends and family who celebrated the arts, and actively created work. I remember attending galleries in their living rooms, and later visiting showings in Downtown Denver and eventually NYC. We all did this in the tradition of going to visit artworks on the first Friday of the month.

First Friday is a small national holiday at the beginning of the month where galleries open their doors, invite in all the public, and put artists next to their work.

First Friday became an important part of my life and always reminds me of good times looking at people’s creation. During showings, we talked about life, gave thoughts, feedback, and sometimes purchasing work that meant something to me.

Now I create work, and send it in the mail, but never get too much time to share and celebrate – till now.

This is the First Friday of November, and here is a small selection of the work that I’ve been hoarding over the last month for today to share with you.

It’s a sneak peek of what I’ll be formally posting to my portfolio through the next month. The first post is already up.

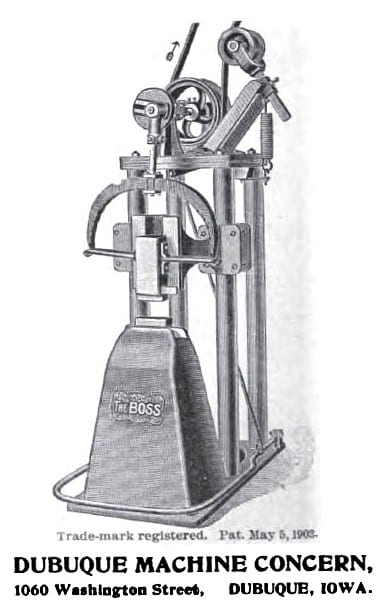

In this, you’ll see a For Barber’s Use with titanium lined burl, a “buster sword” inspired kamisori, and collaborations with brands that want to share straight shaving with their customers.

Every day I’m honored to make fine razors for you, and my only hope it to continue to improve, and make them a bit faster.

Cheers, happy first Friday, and visit a local gallery if you have some time left in the day.