Had fun photographing this very shiny, very elvish style blade.

My small shop forges on without interruption.

If you want to check in on your order, or just need someone to chat with, drop a line any time. I’ll try to keep up with email.

Until otherwise posted, I’ve chosen to settle in my shop through this, since it’s a solitary place, where I work with no one, and can responsibly continue what I do.

To all, I send my most heartfelt wishes for wellness during these terrible circumstances.

Please take time to enjoy and support those around you, while noting the simple enjoyments of life that become so important, and clear, during times like this.

-Christopher

Sneak peek at an upcoming post to the portfolio. This blade is made with random pattern damascus steel, and beastly 8/8 sized blade with a classic notched tip. Scales are a resin set alongside buckeye burl, with roughly polished metal backing (to be seen through the translucence blue).

Nice oceanic feel to the design, so I thought the name “riptide” was fitting.

What Kamisori straight razors look like freshly forged off the anvil.

This batch is done, with some shipping to customers soon, and a few put into stock.

From this photo, the razors have several stages (with lots of sub steps) before they are ready for the shave:

- Forge

- Rough grinding the hollows

- Heat treatment (in-house)

- Finish grinding

- Bevel set

- Engraving

- Honing

- Packaging

Thank you to my customers

Here’s a bit about Andre, in his own words:

Seven facts about Andre:

- My favorite music artist is neffex

- I love learning new skills and gathering knowledge

- I’m a gamer

- Play D&D and MTG

- I love reptiles

- Since I grew up in Colorado, I enjoy camping

- I enjoy studying Blades, Archery, and Firearms

Mr. Pratt sent me his Boker straight razor for a touch up on the hones, and asked me to do an engraving as well.

He asked for a medieval theme to the text, so I did his last name. Fits the German theme of this blade.

Afterwards, I took the edge up from my typical stone progression (1K – 5K – 8K – Y/G Escher, Bridle Strop).

Fine blade, and far more interesting with a touch of personality along the grind.

These are the moments where I kind of feel like a tattoo artist – quite fun.

Custom Engraving Service

A recent favorite piece.

I really enjoy colliding natural materials and processes in ways that I haven’t been done before.

It really show how a little bit of improvisation mixed with my favorite crafting processes can create a blade with visuals that are hard to ignore.

This razor ended up with a great energy, and I plan to do many more.

Get A Custom Straight Razor

Hope everyone had a great Father’s Day, and enjoyed good time with people they love.

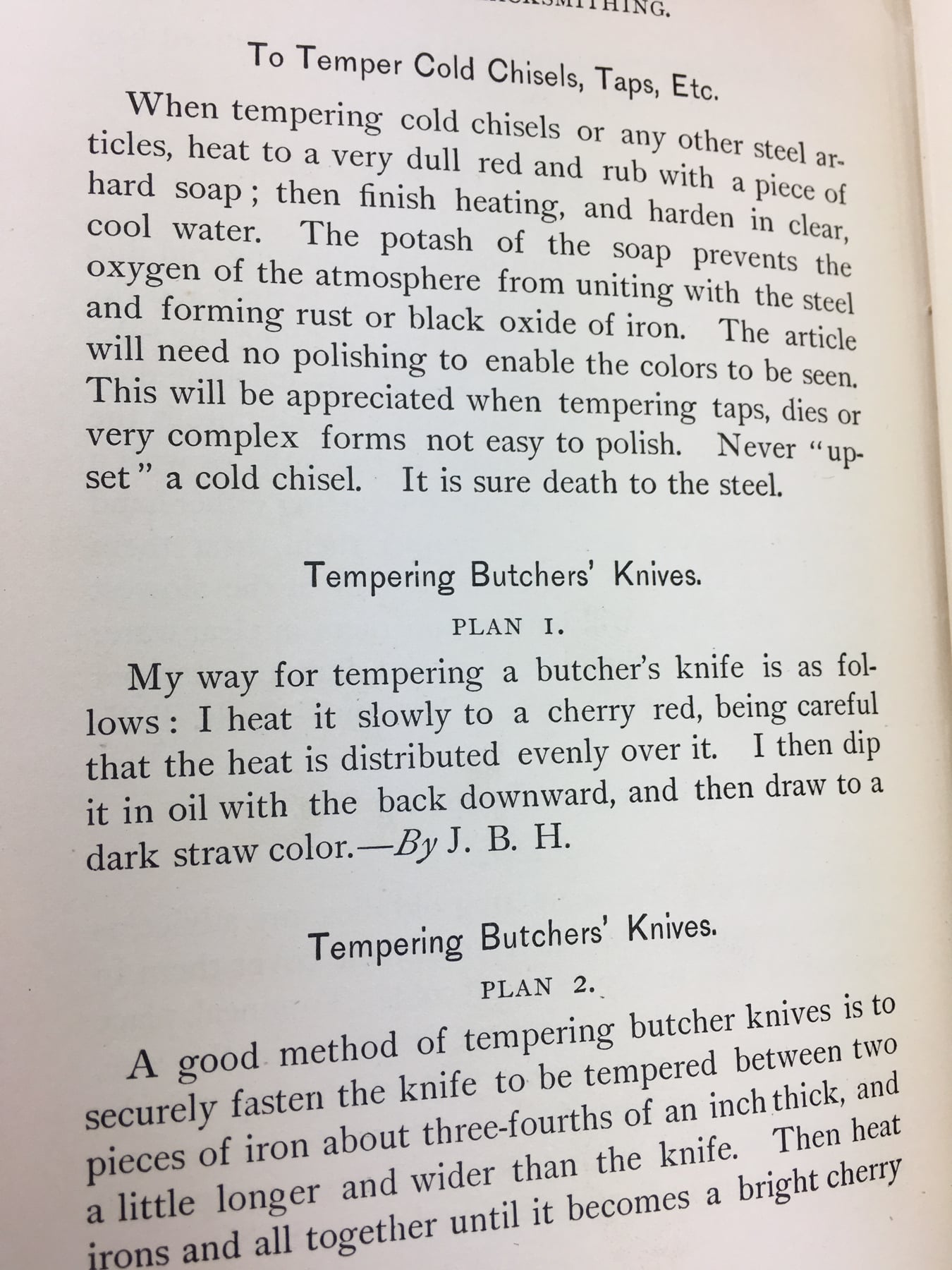

This weekend I was generously gifted a fine antique book by my brother.

I thought I’d share a page of it’s highly technical procedure on steel temperance.

I searched through this book for the “website updates for blacksmiths”, but couldn’t find it. It may be in a future edition.

You’ll note that I’ve been posting photos of work to my website, and making updates. It’s been fun, but not as much fun as working at the anvil or grinder.

Also, I spent some time with family recently to help out.

This put me behind on my emails, and I’ll be catching up with these through the week.

Fine steel being posted soon, and more.

Happy Monday, and happy summer,

-Christopher

Egyptian goddess engraved into D2 steel, paired with blonde ox horn scales, and greek engraving.

I really enjoyed completing this piece because it reminds me of the old masonic style razors.