A great week away celebrating my sister’s wedding, and now I’m back in the shop.

A little glimpse into the production of the gold wedding band that I crafted for her husband, with lots of firescale. Looked much more like 14K gold after some polishing and a bath in jeweler’s pickle.

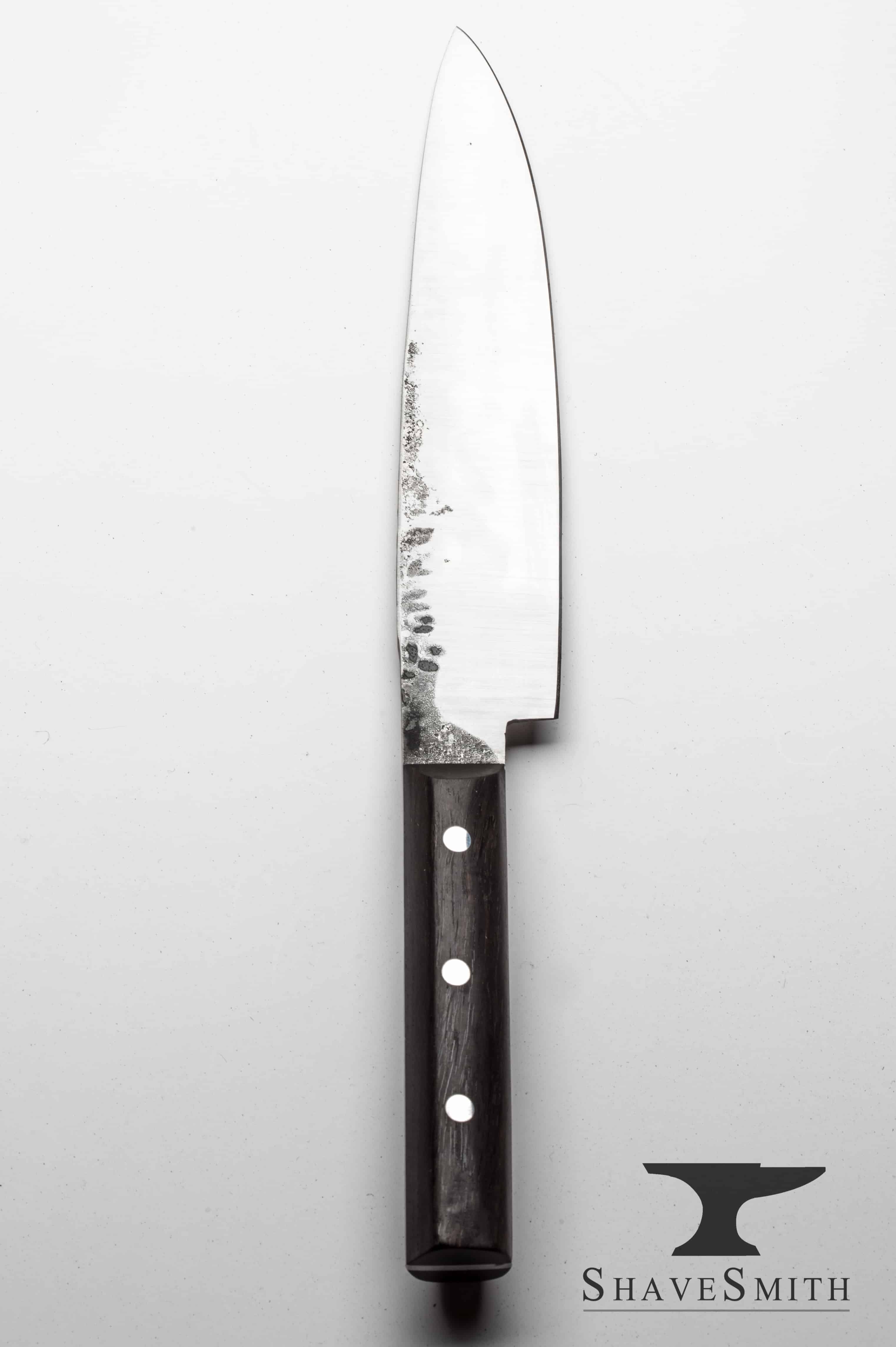

Also, one of the unposted custom blades I finished in somewhat recent time. Damascus, ox, and a hefty beard chopper.

Catching up on emails today, and working my way back into the craft (back to the grind, literally, and happy for it).

-Christopher